Are you worried about low production efficiency as your order volume keeps increasing?

Choose a machine integration automation solution to achieve smart automated production, giving your company a competitive edge in the market.

Provide the following services to assist you in establishing an automated production line.

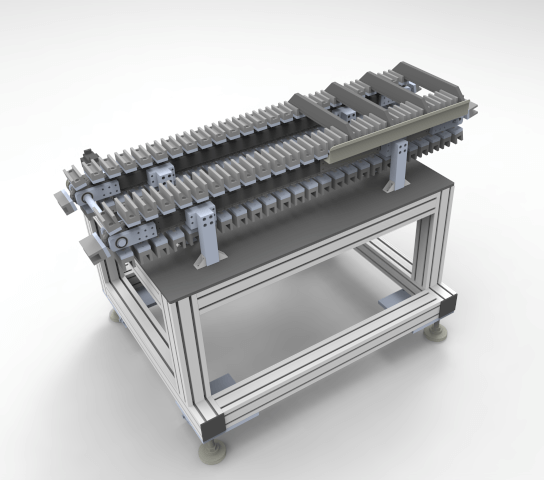

Planning for Material Infeed and Discharge Systems

Provide comprehensive planning for material infeed and discharge systems, including:

- Vibratory Disc Feeder Infeed System

- Tower Feed Station

- Conveyor Infeed Station

- Rotary Table Infeed System

- Related Infeed Inspection and Design

Standard Machine Retrofit

Professional retrofitting and integration for a complete upgrade of machinery and equipment.

- Mechanical Automatic Door Retrofit

- Mechanical Automatic Side Door Modification

- Equipment Height Increase

- Design of Specialized Fixtures and Positioning Jigs

- Other Related Hardware Integration Services

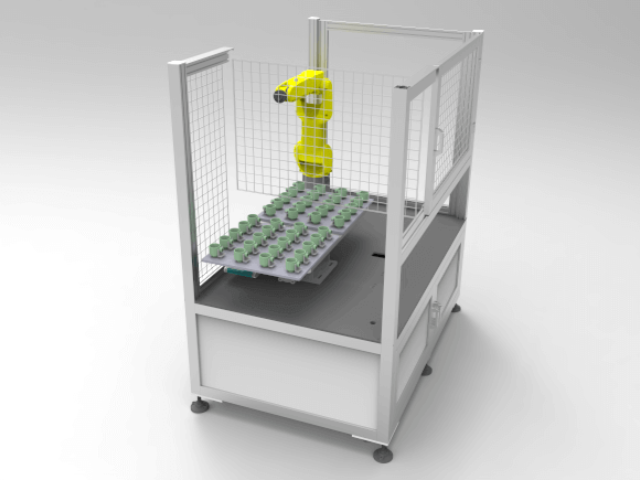

Installation and Configuration of Robotic Arms

- Japanese brands such as FANUC, YASKAWA, and NACHI

- Taiwanese brands such as Delta (DELTA)

- Other brands such as ABB, UR, and EPSON...

Robotic Arm Installation Services Include

- Hardware Installation (Base, Anchor Bolts, Ground Wiring)

- Design of Robotic Grippers

- Design of Robotic Pneumatic Systems

- Handshake Control for Communication Between Electrical Control Systems at Each Station(Handshake)

- Overall System Supervisory Control and Human-Machine Interface(HMI)

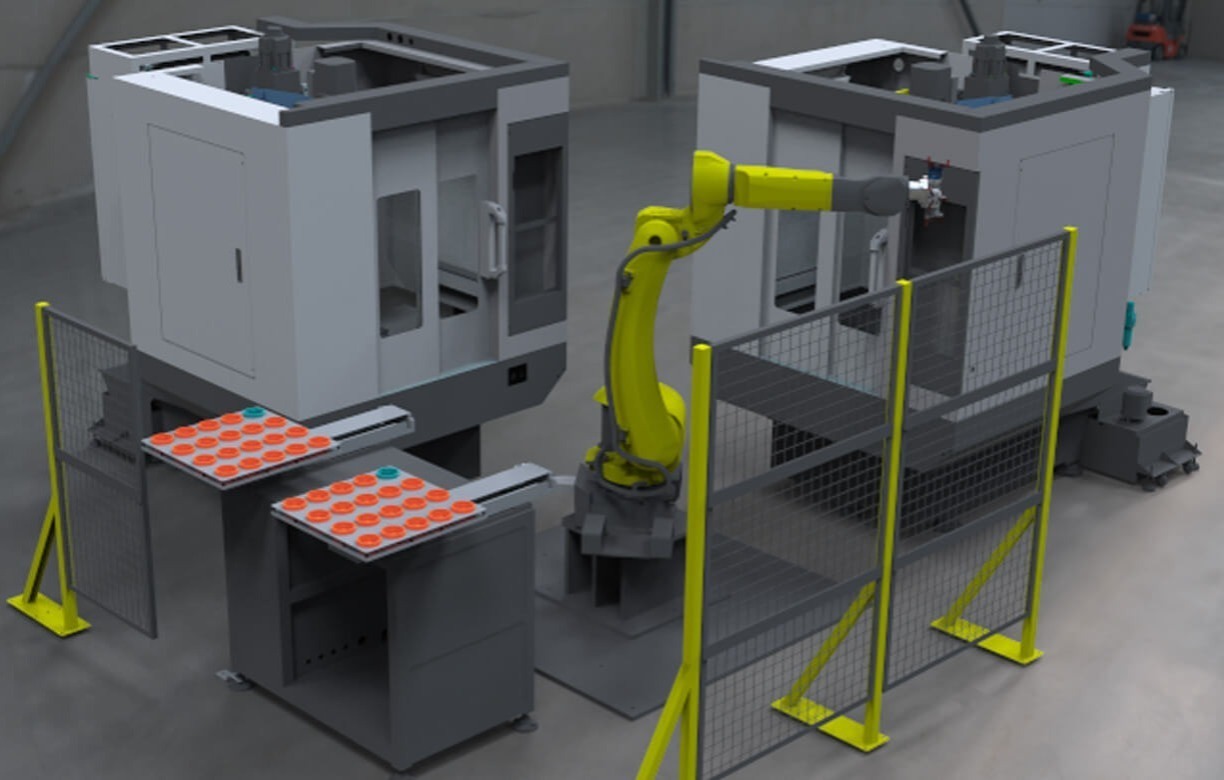

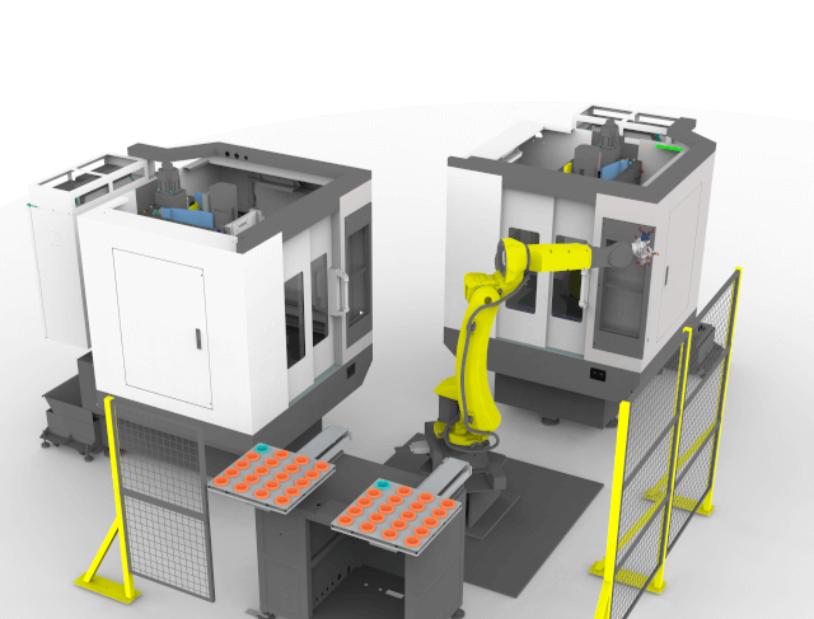

Processing Unit and Processing Station

Machining cell

Our company has established a processing unit integrated with machining equipment, automation systems, and robotic arms.

Safety and Energy-Efficient Design

We offer safety designs for automation equipment, including safety fences, interlocks, and light curtains, as well as optional solutions like smart meters and energy data collection.

Achieving Industry 4.0: Moving Towards the Future of Smart Manufacturing and Smart Factories.

Choose our robotic arm integration solutions to not only achieve automation and intelligence but also to stay at the forefront of Industry 4.0. With 40 years of manufacturing experience and professional service, we are committed to helping you stand out in the processing market and realize true smart manufacturing and smart factories.

SHANG ZUAN CO., LTD.

SHANG ZUAN CO., LTD.