Y axis travel: 400mm

Z axis travel: 330mm

Spindle nose to work surface: 150~480mm

Worktable size: 650*400mm

Worktable Height (from Ground): 800mm

Spindle Speed Range: 12,000rpm (Power:5.5kw)

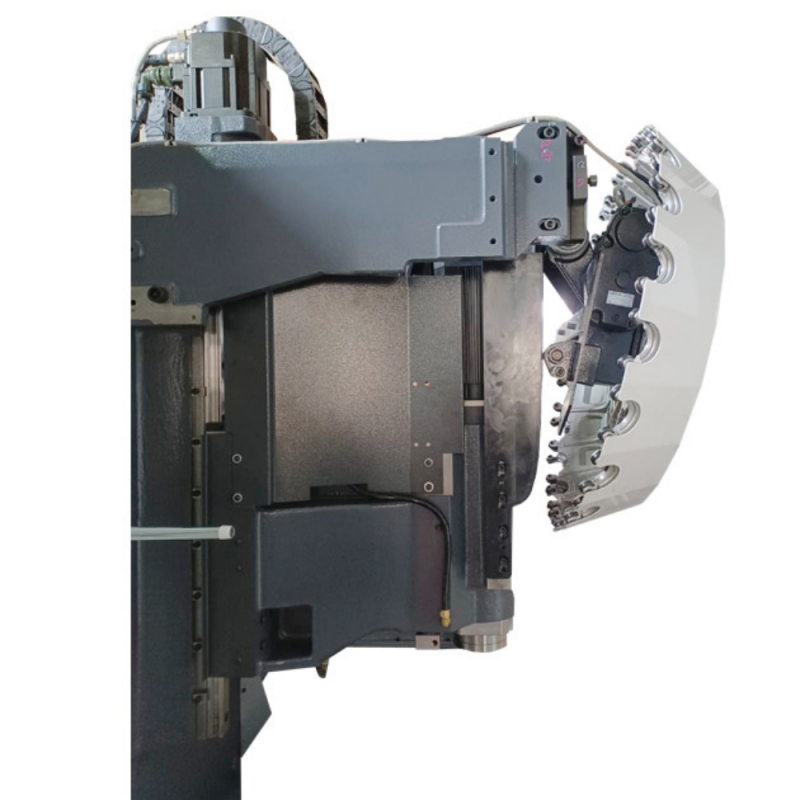

Tool System: BT-30, upgrade to 21 tools

High-Speed Tool change Upgrade

Tri-Color Warning Light

Net Weight of the Machine: 2800kg

Precision Machining Automated CNC Machines

With 40 years of craftsmanship, we have introduced a CNC machine specifically designed for large-batch processing. This CNC machine integrates drilling, tapping, and milling functions, enhancing efficiency and meeting diverse needs, revitalizing your machining operations.

Committed to Boosting Machining Efficiency

High-speed operation is extremely stable, and the lightweight design makes it more energy-efficient compared to other CNC machines.

6 Major Advantages

Our CNC machines focus on production efficiency, optimizing speed and quality from the very beginning. Choose BEECNC for a seamless, cost-effective manufacturing process that truly maximizes your results.

1.Space Savings : 60% more compact: The footprint is reduced by approximately 60% compared to standard machine tools. With the same spacing, the front machine setting ratio is 3:2.

2.Energy Savings-35% energy and 50% air savings : The DTC series is designed for energy efficiency and environmental friendliness. Features include : 1.Pneumatic source management. 2.Lightweight structural components to reduce power consumption. 3.The grease lubrication system minimizes oil usage and environmental impact.

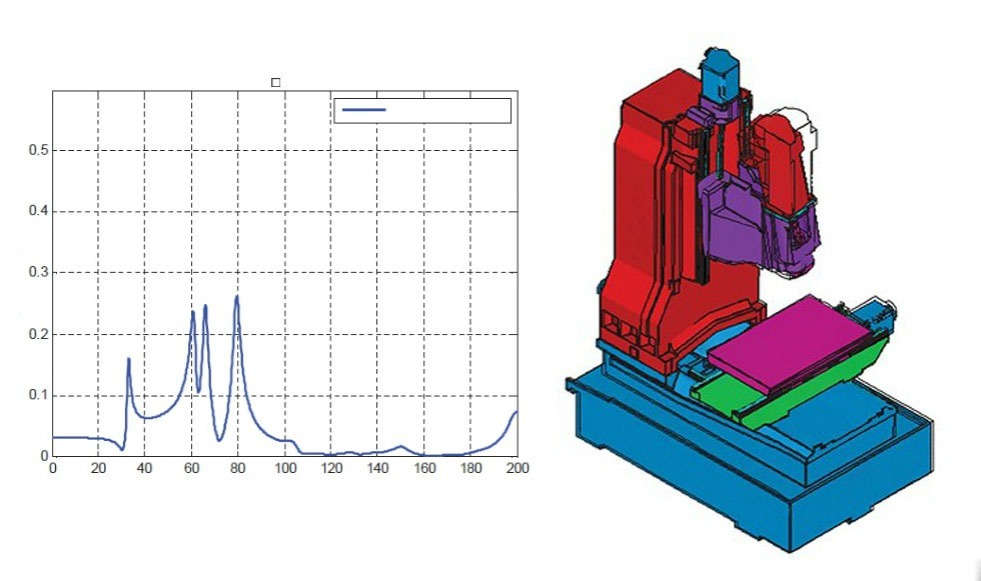

3.Structural Rigidity : 15% stronger performance : Designed with Finite Element Analysis (FEA) for the entire machine. Validated through over 12 scientific tests, including : 1.Axial static rigidity ; 2.Overall machine dynamic rigidity ; 3.Modal analysis ; 4.Feed system rigidity. Compared to similar products, there is a 20% weight reduction and a 15% improvement in rigidity.

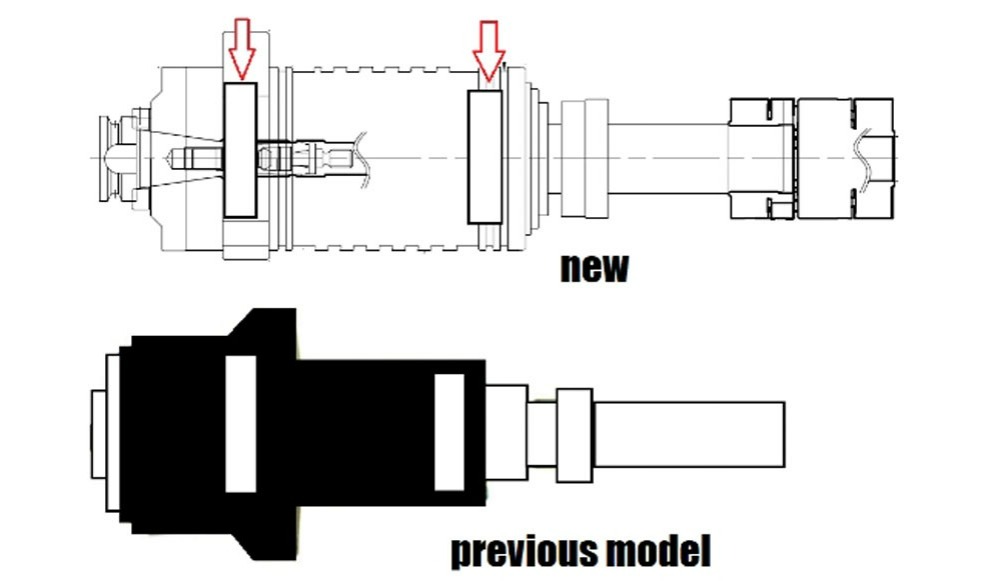

4.Component Upgrades : Better spindle and transmission components : 1.New wide-span spindle. 2.Heavy-duty linear guideways and ball screw system.

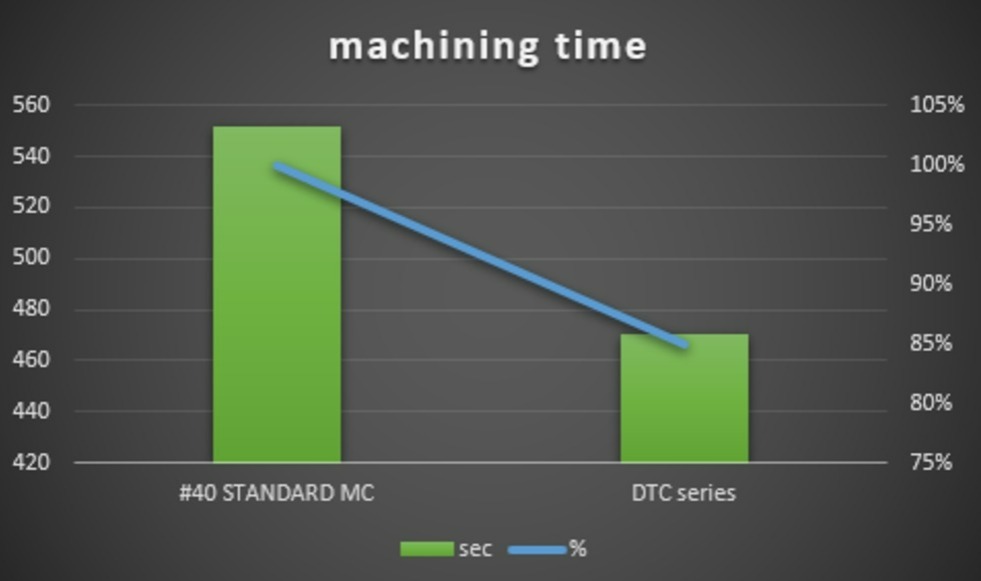

5.Fast - 12% more daily output : servo tool changer, tool change time reduced by 30%, rapid traverse rates: 48 m/min x 48 m/min x 48 m/min.

6.Quick Payback : Easily reclaim your investment. The BeeCNC DTC series is ideal for secondary processing, formed metals, and mass production workpieces. Compared to the #40 standard milling machine, the DTC series offers high speed, low consumption, and low investment costs. Achieve faster ROI with your equipment investment.

CNC machines have a small footprint, saving you more space.

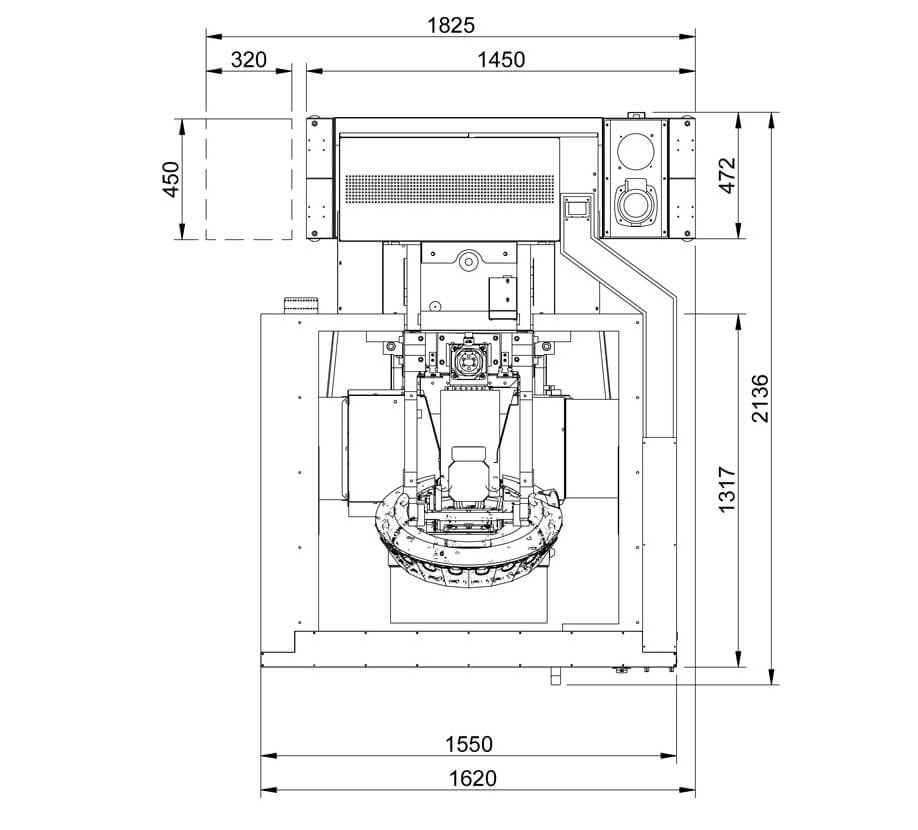

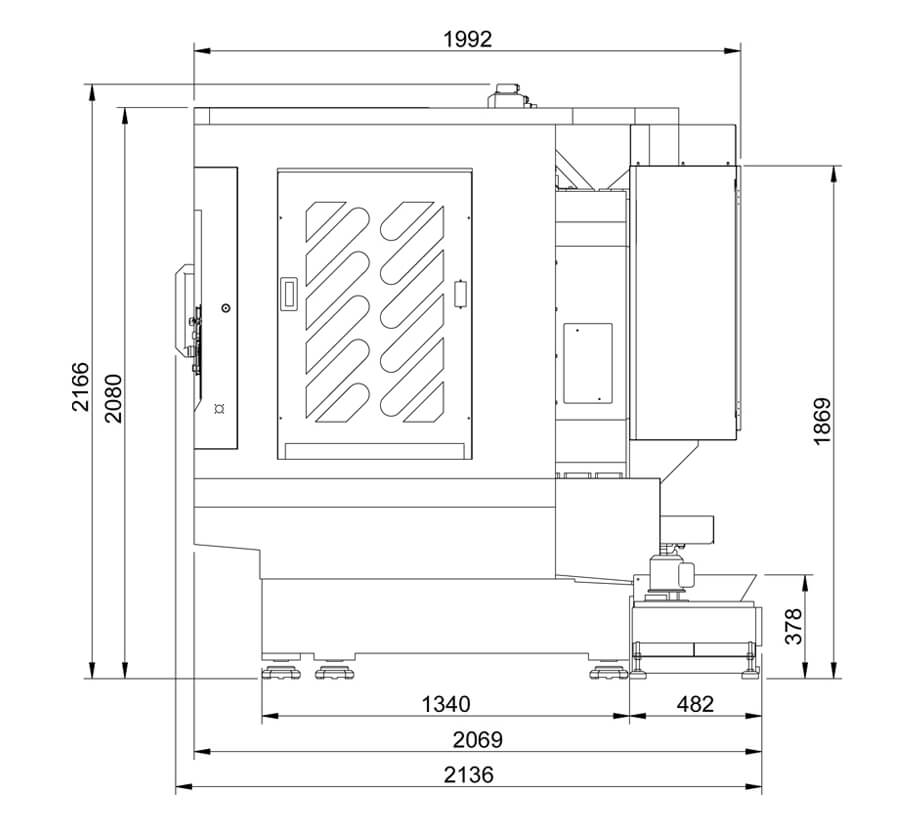

Machine Dimensions: Length 162cm * Width 213cm * Height 216cm

100% Commitment to Made in Taiwan.

40 Years of Technological Expertise in Taiwan, Cultivating Excellence in Quality.

The Best Choice for Industry 4.0 Smart Manufacturing.

Automatic loading and unloading system compatible with various brands of robotic arms, saving you more labor costs.

Comprehensive Pre-sales and After-sales Services

Absolutely Your Most Trusted Partner

-

Machining Capabilities : With capabilities for drilling, tapping, chamfering, and milling, this machine meets a variety of machining needs.

-

Wide Expandability : Compared to custom machines that can only process a single artifact, CNC machines can handle a wider variety of items, achieving the best return on investment.

-

High Stability : This CNC machine has sold over 70 units and has successfully resolved all issues encountered during the initial development phase, ensuring its durability and stability.

-

Special Pricing : According to market research, the cost of individual CNC machines is approximately 49,000 USD for Japanese brands and about 39,000 USD for Taiwanese brands. Our CNC machines have the same specifications as Japanese brands, but our pricing is more competitive than that of Taiwanese brands.(Welcome to request a quotation)

-

Added value : After purchasing the machines, you can opt for our design services for jigs and fixtures to assist in integrating and planning efficient workstations.

-

Prompt service : If you encounter any issues, please feel free to reach out to us. We will promptly provide professional support to ensure the long-term stable operation of your CNC machines.

-

Professional manufacturing : With 40 years of accumulated expertise in machine tool manufacturing, we focus on producing each CNC machine to ensure exceptional quality.

左右滑動看表格

左右滑動看表格| Specifications | Unit | DTC-500 | ||||

| Travel | X axis travel | mm | 500 | |||

| Y axis travel | mm | 400 | ||||

| Z axis travel | mm | 330 | ||||

| Distance from spindle nose to work surface | mm | 150-480 | ||||

| Worktable | Worktable size | mm | 650*400 | |||

| Max. load (Average) | kg | 300 | ||||

| Work surface height (above ground) | mm | 800 | ||||

| Spindle | Taper type | BT-30 (Direct connection) | ||||

| Speed range | rpm | 12000 / 24000 (OPT) | ||||

| Feed rate | Rapid feed rate | m / min | X、Y、Z-48m / min | |||

| Cutting feed rate | m / min | X、Y、Z-10m / min | ||||

| Automatic tool changing system | Tool specifications | BT-30 | ||||

| Maximum tool diameter | mm | Ø80mm | ||||

| Number of tools | 21 | |||||

| Maximum tool length | mm | 250mm | ||||

| Tool weight | kg | 2Kg | ||||

| Spindle HP / KW | Spindle | KW | 3.7-7.5KW | |||

| X axis | HP / KW | 2.0HP / 1.5KW | ||||

| Y axis | HP / KW | 2.0HP / 1.5KW | ||||

| Z axis | HP / KW | 2.68HP / 2.0KW | ||||

| Controller System | Taiwan Delta, Japan Mitsubishi, and FANUC (three options available) | |||||

| Machine Weight | 2800kg | |||||

左右滑動看表格

左右滑動看表格

CE and TS standards、ISO 14955、Machine tools Environmental evaluation of machine tools

Optional Accessories

The CNC machine does not include optional accessories. For inquiries, please feel free to contact our customer service.

Add 4th axis

When a workpiece requires multiple machining operations, you can choose to add a 4th axis. This allows for 360-degree rotation, enabling multi-surface machining.

Tool Setter

In general, manual measurement is sufficient. Automatic tool measurement should only be considered if the factory is implementing full automation.

Chip Conveyor

Purchasing is only necessary when there is no reserved space behind the CNC machine or when there is a need to automatically deposit metal chips onto a cart.

Coolant Through Spindle

If the product to be machined has a large depth-to-width ratio and requires deep drilling, we recommend purchasing this option.

Oil cooler

A CNC machine is needed only if it will be used at high speeds for long periods.

Oil Mist Collecto

When using pure oil for cutting, the air can become quite hazy. This equipment will significantly improve air quality.

6 Assurances for Peace of Mind

Choose Us, Choose Professionalism.

Welcome to Test the Machine.

If you are interested in our CNC machines but would like to confirm their suitability, we sincerely invite you to visit our factory for a test. Address: 412 No. 115 Kung Yei 11RD., Dali IDN ZONE, Dali District, Taichung City, Taiwan, R.O.C. Please be sure to call ahead for an appointment to avoid any wait.

High Stability

Since 2019, this CNC machine has been developed and authorized by the Precision Machinery Research Development Center. More than 70 units have been sold. All issues encountered during the initial development phase have been resolved over the years, so durability and stability are definitely not a concern.

After-Sales Service

If you have any issues after purchasing the CNC machine, feel free to contact us at +886-4-24930678, or use our online customer service through Facebook Messenger or WhatsApp. We will provide you with professional after-sales service to quickly resolve any technical problems you encounter, ensuring that your CNC machine operates reliably and consistently over the long term.

Worry-Free Inventory

Our company maintains a sufficient inventory of CNC machine parts to ensure that we have stock available for maintenance and replacement. This means you don’t have to worry about parts shortages. We are a CNC machine factory you can absolutely trust.

Two-Year Warranty

Our CNC machines come with a two-year warranty, ensuring that the CNC machines you purchase maintain high stability during operation in your company, giving you peace of mind.

Value for Money

Our CNC machines are developed based on models from leading Japanese manufacturers, in collaboration with the Precision Machinery Research Development Center. We have reinforced the structure and adjusted the speed. Currently, the drilling and tapping speeds are comparable to those of Japanese brands. With the quality of Taiwanese manufacturing and a more affordable price, you can achieve the highest performance CNC machines at a competitive cost, ensuring the best return on investment.

Invest in the Future, Make Better Choices

Don't let cumbersome processes slow down your production efficiency. Let us help you enhance your machining competitiveness.

SHANG ZUAN CO., LTD.

SHANG ZUAN CO., LTD.