Min. Spindle PCD : 38mm (4-spindle)

Min. Spindle Pitch By Every 2 Spindles : 27mm

Max. Working Capacity-Drill Capacity : 8mm

Max. Working Capacity-Tapping Capacity : M8

RPM Ratio To Main Spindle : 1:1or1:1.3

Numbers Of Spindle : 2-4

Friendly Reminder :

ER Collets And Drill Chuck Models Are Available

-

Max. Spindle PDC : 125mm

Min. Spindle PCD : 38mm (4-spindle)

Min. Spindle Pitch By Every 2 Spindle : 27mm

Max. Working Capacity-Drill Capacity : 8mm

Max. Working Capacity-Tapping Capacity : M8

RPM Ratio To Main Spindle : 1:1:or1:1:3

Numbers Of Spindle : 2-4

Friendly Reminder :

ER Collets And Drill Chuck Models Are Available -

Max. Spindle PDC : 100mm

Min. Spindle PCD : 25mm (4-spindle)

Min. Spindle Pitch By Every 2 Spindle : 18.7mm

Max. Working Capacity-Drill Capacity : 6mm

Max. Working Capacity-Tapping Capacity : M6

RPM Ratio To Main Spindle : 1:1:or1:1:3

Numbers Of Spindle : 2-4

Friendly Reminder :

ER Collets And Drill Chuck Models Are Available

-

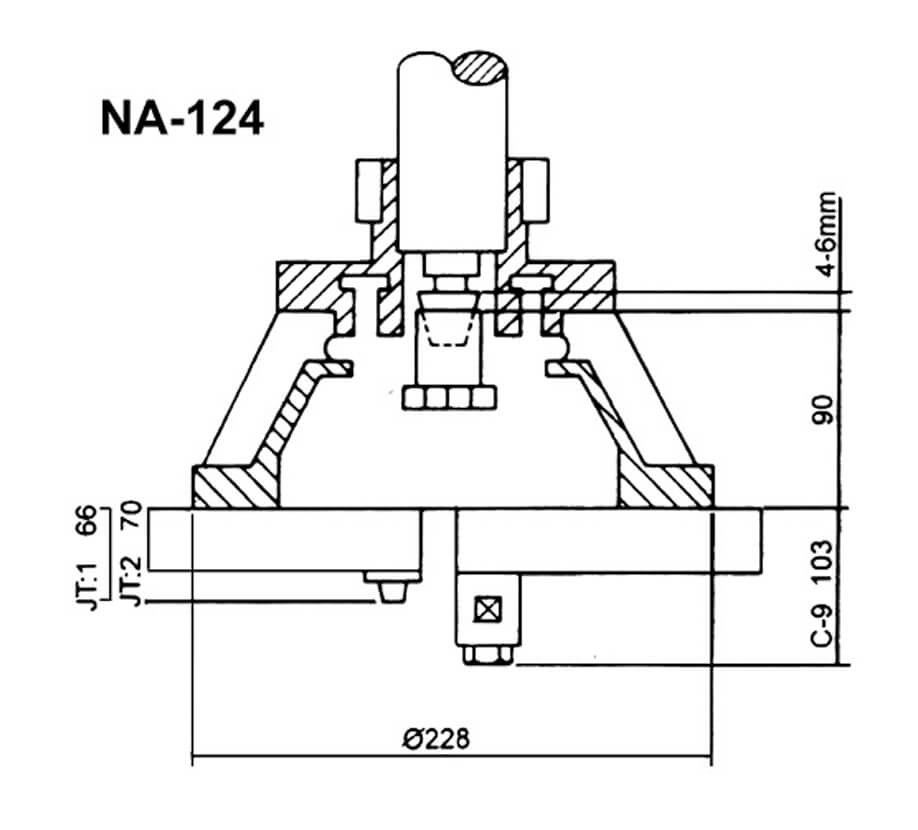

NA-124 DimensionsMax. Spindle PDC : 125mm

Min. Spindle PCD : 38mm (4-spindle)

Min. Spindle Pitch By Every 2 Spindle : 27mm

Max. Working Capacity-Drill Capacity : 8mm

Max. Working Capacity-Tapping Capacity : M8

RPM Ratio To Main Spindle : 1:1:or1:1:3

Numbers Of Spindle : 2-4

Friendly Reminder :

ER Collets And Drill Chuck Models Are Available -

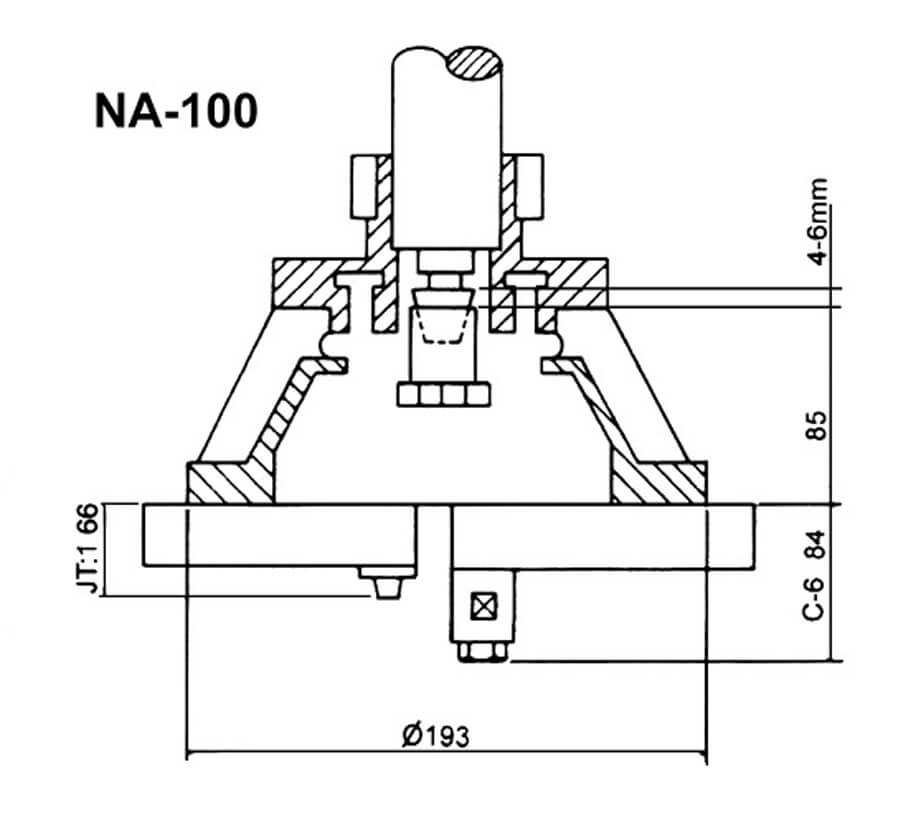

NA-100 DimensionsMax. Spindle PDC : 100mm

Min. Spindle PCD : 25mm (4-spindle)

Min. Spindle Pitch By Every 2 Spindle : 18.7mm

Max. Working Capacity-Drill Capacity : 6mm

Max. Working Capacity-Tapping Capacity : M6

RPM Ratio To Main Spindle : 1:1:or1:1:3

Numbers Of Spindle : 2-4

Friendly Reminder :

ER Collets And Drill Chuck Models Are Available

左右滑動看表格

左右滑動看表格| Related Multiple Spindle Head Dimensions | ||

| Dimensions | NA100 | NA124 |

| Max. Spindle PCD(mm) | 100 | 125 |

| Min. Spindle PCD(mm) | 25 (4-Spindle) | 38 (4-Spindle) |

| Min. Spindle Pitch By Every 2 Spindles (mm) | 18.7 | 27 |

| Max. Working Capacity-Drill Capacity(mm) | 6 | 8 |

| Max. Working Capacity-Tapping Capacity | M6 | M8 |

| RPM Ratio To Main Spindle | 1:1or1:1.3 | 1:1or1:1.3 |

| Numbers Of Spindle | 2-4 | 2-4 |

Combining drilling and tapping in one unit for multi-hole processing is the best choice for enhancing efficiency.

- 100% Made in Taiwan, committed to providing customers with the best multiple spindle heads.

- Custom specifications can be tailored to meet the requirements of different workpieces.

- The multiple spindle head can complete multi-hole processing in one go, improving your work efficiency.

Introduction to the multiple spindle drilling machine.

Assembly of the multiple spindle head.

If a quotation is needed.

Please provide the following four pieces of information in detail.

Numbers Of Spindle

Drilling and tapping diameter

Spindle spacing

Workpiece material

4 Assurances for Peace of Mind

Choose Us, Choose Professionalism.

After-Sales Service

If you have any issues after purchasing the Multiple Spindle Head, feel free to contact us at +886-4-24930678, or use our online customer service through Facebook Messenger or WhatsApp. We will provide you with professional after-sales service to quickly resolve any technical problems you encounter, ensuring that your Multiple Spindle Head operates reliably and consistently over the long term.

Worry-Free Inventory

Our company maintains a sufficient inventory of Multiple Spindle Head parts to ensure that we have stock available for maintenance and replacement. This means you don’t have to worry about parts shortages. We are a Multiple Spindle Head factory you can absolutely trust.

Customized service

If you want to customize a special multiple spindle head, we have a dedicated department that can provide tailored services to meet your various multi-hole drilling and tapping processing needs, thereby improving your production efficiency.

Value for Money

Our multiple spindle heads offer excellent quality at highly competitive prices, allowing you to achieve the highest performance with a reasonable cost and realize the best return on investment.

SHANG ZUAN CO., LTD.

SHANG ZUAN CO., LTD.