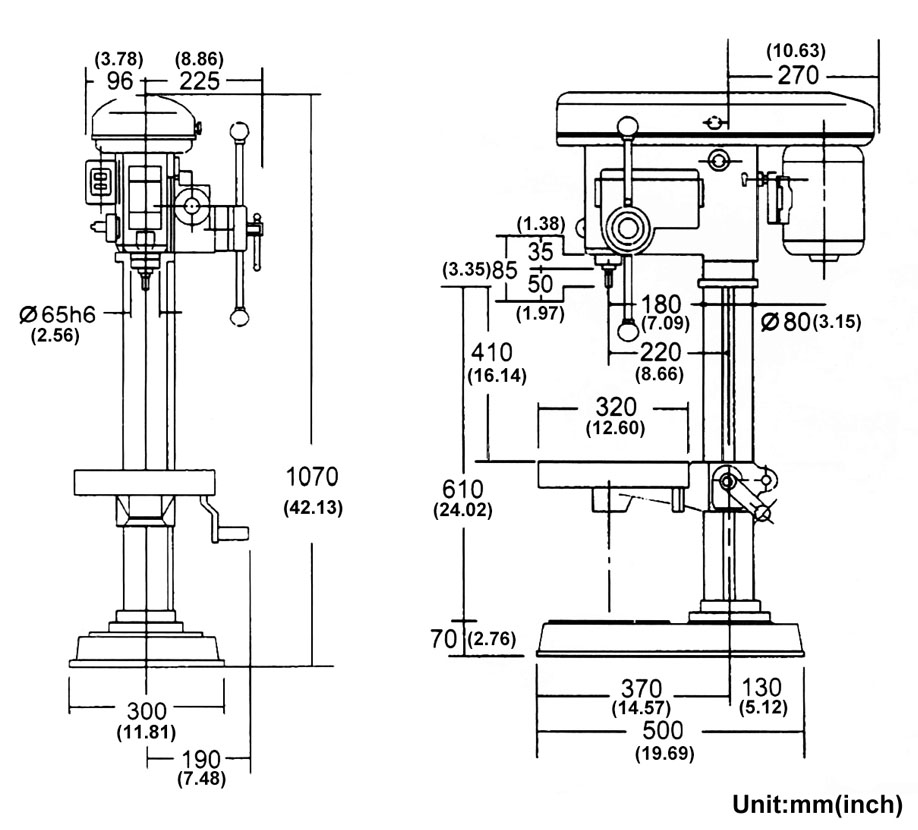

Spindle Type-Inside Spindle : MT2

Spindle Type-For Chuck : JT6

Working Ability-Steel (S45C) : 3-16

Spindle Travel : 100mm

Motor : 1HP-4P

Spindle Speed RPM (Steps) :

50HZ : 190-2800

60HZ : 240-3400

Weight : 94kg

-

Stroke : Manual

Spindle Type-lnside Spindle : MT2

Spindle Type-For Chuck : JT6

Working Ability-Steel (S45C) : 3-16

Spindle Travel : 100mm

Motor : 1HP-4P

Spindle Speed RPM (Steps)-50HZ : 190-2800(9)

Spindle Speed RPM (Steps)-60HZ : 240-3400(9)

Weight : 94kg

Friendly Reminder :

1. The practical working abilities are very related to sharpness on drill bit, good lubrication and suitable cooling.

2. Customized spindle speed might be required for particular materials or drilling sizes.

-

SpecificationsStroke : Manual

Spindle Type-lnside Spindle : MT2

Spindle Type-For Chuck : JT6

Working Ability-Steel (S45C) : 3-16

Spindle Travel : 100mm

Motor : 1HP-4P

Spindle Speed RPM (Steps)-50HZ : 190-2800(9)

Spindle Speed RPM (Steps)-60HZ : 240-3400(9)

Weight : 94kg

Friendly Reminder :

1. The practical working abilities are very related to sharpness on drill bit, good lubrication and suitable cooling.

2. Customized spindle speed might be required for particular materials or drilling sizes.

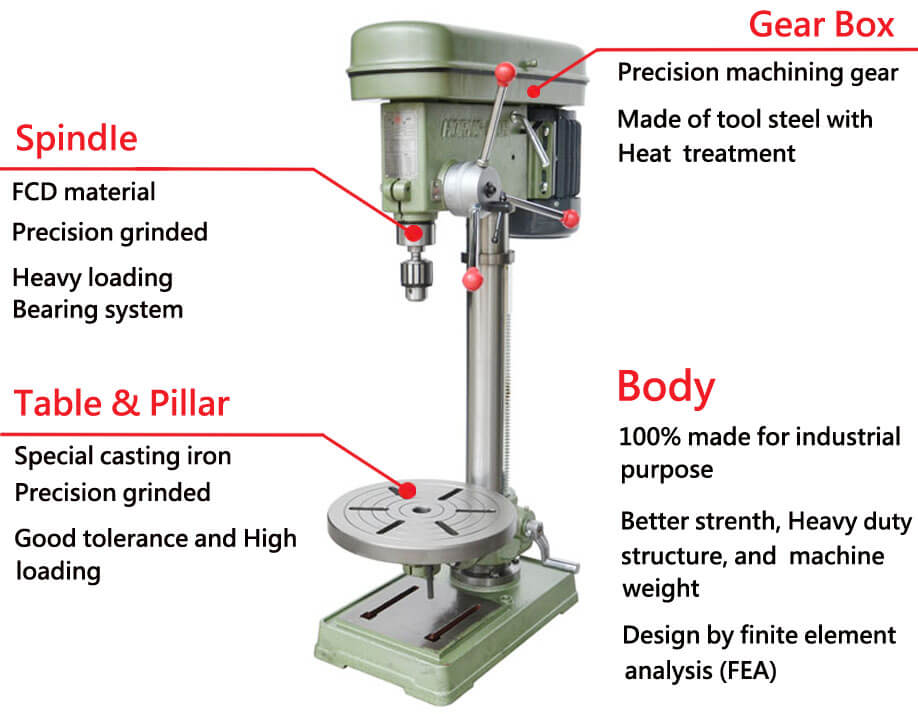

Combining expertise and craftsmanship, it showcases the artisanal quality in drill press manufacturing.

- 100% Made in Taiwan, committed to delivering the best drill press to our customers.

- The drilling machine is meticulously crafted with exceptional workmanship and superior precision.

- The Horng Dar brand manual Bench Drilling Press Machine, produced by BEECNC, is the basic model in all of our advanced product designs. The machine body is made of FC20 casting steel, with a strong and durable structure that ensures stable performance during use.

- The machine provides the precision by its manual operation design in combination with the stable axle center.

- Any drilling machine in the series has a verticality tolerance of less than 0.07mm between the spindle center and the working table (HD-14 has a tolerance of less than 0.05mm). We have thoroughly examined and improved the precision of all the machines.

How to unload drill chuck

How to load drill chuck

How to load/unload the belts

Recommended Drilling Machines

Manual Drilling Machine HD-14I

25mm Standard Manual Drill Press

Stroke : Manual

Spindle Type-Inside Spindle : MT2

Spindle Type-For Chuck : JT6

Working Ability-Steel (S45C) : 3-16

Spindle Travel : 100mm

Motor : 1HP-4P

Spindle Speed RPM (Steps)-50HZ : 400-2700

Spindle Speed RPM (Steps)-60HZ : 400-2700

Weight : 95kg

Manual Drilling Machine HD-14

25mm Standard Manual Drill Press

Stroke : Manual

Spindle Type-Inside Spindle : MT2

Spindle Type-For Chuck : JT6

Working Ability-Steel (S45C) : 3-16

Spindle Travel : 100mm

Motor : 1HP-4P

Spindle Speed RPM (Steps)-50HZ : 480-2300

Spindle Speed RPM (Steps)-60HZ : 550-2700

Weight : 91g

Manual Drilling Machine HD-25

25mm Standard Manual Drill Press

Stroke : Manual

Spindle Type-Inside Spindle : MT3

Spindle Type-For Chuck : JT6

Working Ability-Steel (S45C) : 5-25

Spindle Travel : 140mm

Motor : 2HP-6P

Spindle Speed RPM (Steps)-50HZ : 160-1342

Spindle Speed RPM (Steps)-60HZ : 190-1610

Weight : 199kg

6 Key Assurances

Choose us, choose professionalism

Welcome to Test the Machine

If you are interested in our Drilling Machines but wish to confirm their suitability, we sincerely invite you to visit our factory and test the machines in person. Our address is No. 115, Gongye 10th Road, Dali District, Taichung City. Please be sure to call in advance to schedule an appointment, so we can avoid any delays.

Six-Month Warranty

We provide a six-month warranty for all Drilling Machines, ensuring the stability of your machine during initial operations for your peace of mind. Please note that the warranty does not cover belts and bearings, as these items are considered consumables.

After-Sales Service

We have a professional technical support team available. If you encounter any issues with the drilling machine, feel free to call us at +886-4-24930678, or use our online consultation options (Facebook Messenger or WhatsApp). We will provide you with professional after-sales service to quickly resolve any technical problems you may face, ensuring that your drilling machine operates reliably and consistently over the long term.

Worry-Free Inventory

Our company maintains a sufficient inventory of spare parts for all drilling machines, ensuring that you have immediate access to replacement components for repairs and maintenance. This means you won't have to worry about parts shortages, making us a reliable partner for your drilling machine needs.

Customized Services

If you want to customize drilling machines, drill presses, bench drills, manual and automatic drilling machines, industrial drill presses, pillar drills, fixtures, or jigs, we have a dedicated department that can provide tailored services to meet your diverse drilling and processing needs, ultimately enhancing your production efficiency.

Exceptional Value.

Our drilling machines offer exceptional quality at highly competitive prices, allowing you to obtain the most efficient tapping equipment at a reasonable cost, thereby achieving optimal return on investment.

Yi Chang Machinery Co., Ltd.

Yi Chang Machinery Co., Ltd.